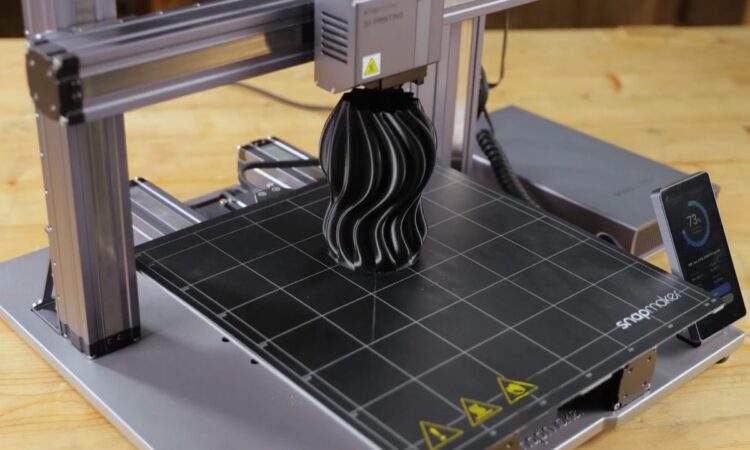

Warping and curling are among the most frustrating and common print failures encountered by both novice and experienced users of the Fused Deposition Modeling (3D printer) process. This phenomenon, where the corners or edges of a printed object lift and curl away from the build plate, leads to failed prints, wasted time, and compromised part accuracy. At its core, warping is a battle against the fundamental physics of thermal contraction. When molten 3D printer filament is deposited and cools, it shrinks. If the material cools and shrinks unevenly—specifically, if the upper layers cool and contract faster than the anchored base layers—it generates internal stress, forcing the base layers to peel up. Eliminating this problem requires a systematic approach, meticulously addressing the thermal, material, and mechanical factors in the printing environment.

Understanding the Physics of Filament Contraction

To solve warping, one must first understand its causes. Every thermoplastic 3D printer filament has a coefficient of thermal expansion (CTE), which defines how much it contracts when cooled. High-performance filaments like ABS or ASA possess a high CTE, meaning they shrink significantly as they drop from their high extrusion temperature (e.g., ) to room temperature (e.g., ). PLA shrinks less, but is not immune.

The critical temperature is the glass transition temperature (), the point at which the solid material begins to soften and lose its rigidity. The key anti-warping strategy is ensuring the bottom layers remain slightly above their until the structure has enough mass and strength to resist the contraction forces from the layers above. This requires managing the temperature in three zones: the nozzle, the build plate, and the ambient environment.

Calibrating Thermal Settings for Different Filaments

Controlling the thermal environment is the most effective solution to counteract warping. This involves precise management of the build plate and the overall air temperature.

Build Plate Temperature Is the Anchor

The heated bed serves as the primary defense against warping. It keeps the base of the print warm, slowing the cooling rate and minimizing the temperature difference between the part’s base and its upper structure.

- PLA: Requires a relatively mild bed temperature, typically between and . This range is sufficient to keep the bottom layers pliable without introducing excessive heat.

- PETG: Performs best with a hotter bed, usually to . This material can sometimes adhere too aggressively, so finding the lowest effective temperature is often preferred to ease part removal.

- ABS and ASA: These high-shrinkage materials require the highest bed temperatures, often to . This intense heat is critical for slowing the cooling rate and preventing rapid, catastrophic contraction.

Optimizing Nozzle and Cooling Fan Speeds

The extrusion temperature should be set at the lowest point within the filament’s recommended range that still allows for smooth, reliable flow. Printing slightly cooler reduces the total thermal energy introduced into the part, minimizing the eventual contraction.

Furthermore, part cooling fans must be used judiciously. For high-warp materials like ABS or ASA, the part cooling fan must be turned off completely to maintain a stable, warm thermal environment around the print. For PLA, fans should be used after the first few layers to solidify the detail, but the airflow should never be directed over the build plate, which would cool the base and induce warping.

Mechanical and Physical Adhesion Solutions

Once the temperature settings are optimized, physical solutions are used to maximize the adherence of the first layer to the build surface, creating a stronger mechanical bond that resists lift.

Ensuring Perfect First Layer Adhesion

The first layer height and compression are paramount. The nozzle should be perfectly leveled and set at a height that slightly squishes the molten 3D printer filament into the build surface. This compression increases the surface contact area and mechanical grip. A calibration check (sometimes called a “first layer test”) should always precede any major print to confirm optimal nozzle-to-bed distance.

Using Adhesion Aids and Surfaces

Different build surface materials and coatings offer varying degrees of adhesion:

- Temporary Adhesion Promoters: Applying a thin, uniform coating of a specialized polymer adhesive (e.g., liquid glue or formulated spray) directly to the build surface significantly enhances the grip for materials like PLA and PETG. For higher-temperature filaments, specialized slurry solutions are often required.

- Permanent Surfaces: Flexible build plates with specialized textured coatings offer excellent adhesion when heated and allow for easy, non-destructive part removal once cooled. Glass surfaces can provide an extremely smooth bottom finish when properly coated with an adhesion promoter.

Adding Structural Anchors

Software-generated structures added around the base of the part can physically anchor it to the bed, increasing the area over which contraction forces are distributed:

- Brim: A brim is a single-layer, flat perimeter attached directly to the base of the part. It acts like an outrigger, requiring the contraction forces to lift a much larger surface area, greatly reducing the likelihood of curling corners.

- Raft: A raft is a multi-layer base printed underneath the entire object. While it uses more material and time, it completely isolates the print from minor surface imperfections on the build plate, providing its own stabilized foundation.

Environmental and Material Pre-Emption

The final step involves managing the overall environment and the quality of the raw material itself.

The Mandate of the Enclosure

For any 3D printer consistently working with high-shrinkage materials (ABS, ASA, Nylon, etc.), an enclosed chamber is not optional—it is mandatory. The enclosure blocks cold drafts and maintains a high, stable ambient temperature, drastically reducing the thermal gradient between the printing plastic and the surrounding air. This uniform thermal environment is the most effective way to eliminate the thermal stress that causes severe warping. The efficiency and consistency of the 3D printer are significantly improved when environmental control is maintained.

Controlling Filament Moisture

Moisture content, though not a direct cause of thermal warping, severely exacerbates print issues. Wet 3D printer filament contains microscopic water bubbles that vaporize when reaching the hot end. These explosive steam bubbles disrupt the smooth flow of the plastic, causing uneven layer deposition, poor adhesion, and structural weaknesses that make the print more susceptible to curling under thermal stress. Drying the filament in a dedicated dehydration unit or controlled oven before printing is a crucial preemptive step.

Conclusion

Warping and curling are solvable problems that demand a comprehensive strategy. The solution involves a layered defense, starting with understanding the thermal properties of the specific 3D printer filament being used. By skillfully setting the build plate temperature to manage internal stress, adjusting the cooling fans to control heat dissipation, ensuring perfect first-layer adhesion with physical anchors or promoters, and—critically—utilizing an enclosure for high-temperature materials, operators can virtually eliminate curling. By mastering this multi-faceted approach, users can unlock the full potential of their 3D printer to produce strong, dimensionally accurate, and professional-quality parts consistently.